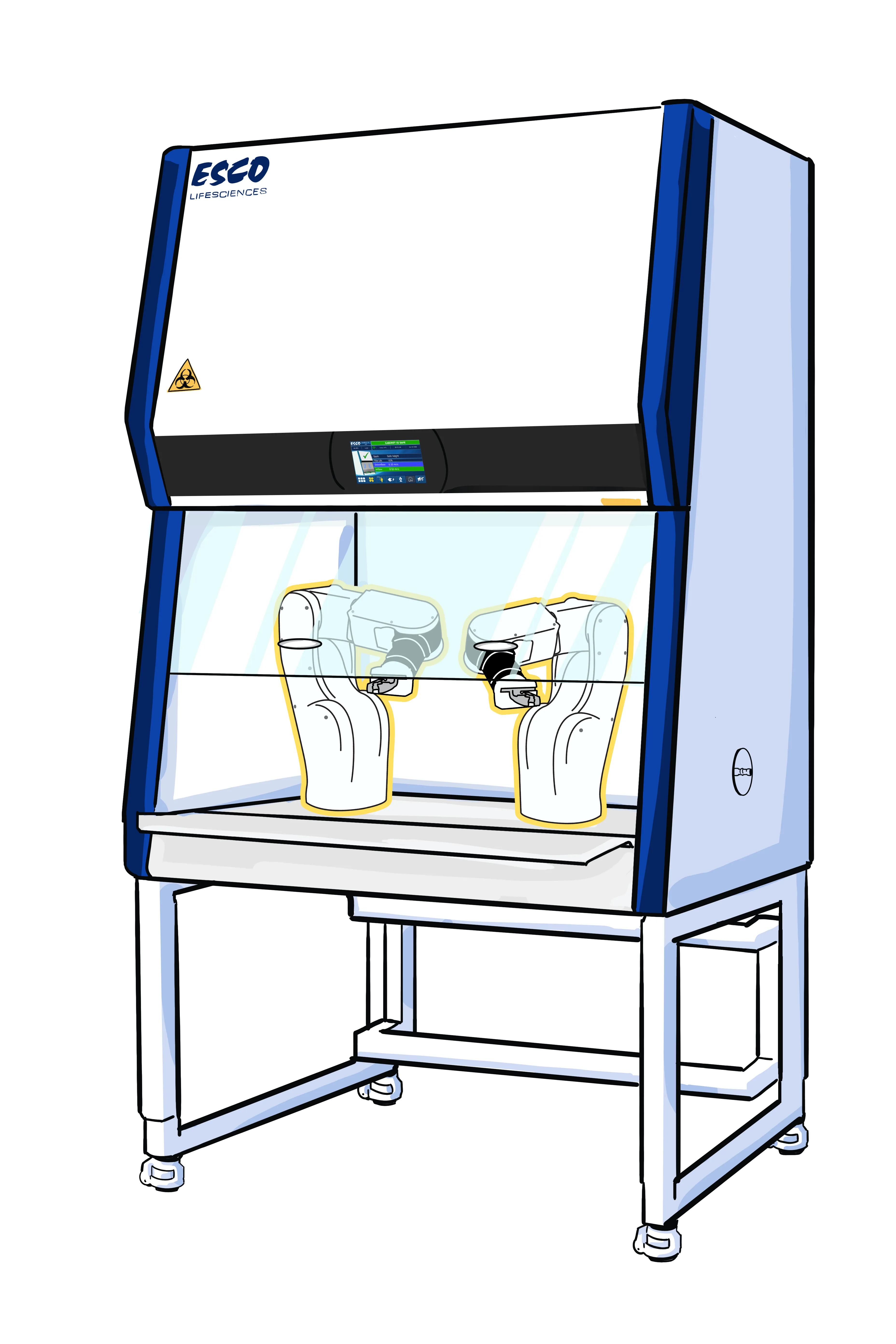

Can Large Automated Equipment Be Safely Integrated into a Biosafety Cabinet?

Placing large-sized automated equipment inside a Biosafety Cabinet (BSC) is generally not recommended, as it can obstruct airflow, compromise sterility, and threaten research integrity. However, as laboratories increasingly adopt robotic systems, a critical question arises: what if the samples processed by automated equipment are sensitive materials that require biosafety protection?

Why Does Automation Equipment Need a Biosafety Cabinet?

Many laboratories now process sensitive biological samples using

automated systems such as robotic liquid handlers, flow

cytometers, cell sorters, and bioprinters. These systems offer

advantages in speed, precision, consistency, and data quality.

However, when handling primary cells, viruses, genetically

modified organisms, or patient-derived materials, additional

protection is required to safeguard operators, samples, and the

environment.

Automated equipment is usually made for standard laboratory

benches. These benches do not offer enough protection against

cross-contamination, aerosol generation, or accidental exposure.

Some systems have internal filters. However, these filters only

protect the samples inside the instrument; they do not protect

operators or the surrounding environment.

For this reason, integrating automated equipment with a Class II Biosafety Cabinet becomes necessary to ensure operator protection, product sterility, and environmental safety in accordance with ISO Class 5 airflow standards and applicable regulations.

The Challenge of Integrating Automation into

a Biosafety Cabinet

Once the need for biosafety protection is addressed, the next

challenge is integration. Biosafety Cabinets are generally

designed in sizes ranging from 3–6 ft and are intended for

manual work performed by operators. In contrast, automated

systems such as liquid handling platforms and flow cytometers

often exceed the height, width, and weight limitations of a

standard BSC.

Even when equipment can physically fit inside a cabinet, its

presence may disrupt unidirectional airflow, compromise

sterility, and reduce overall safety. Placing large objects

inside a standard BSC is therefore strongly discouraged, as it

undermines the cabinet's primary function.

In addition to airflow concerns, automated systems may introduce

vibration, heat generation, and increased electrical and data

connectivity requirements.

If not properly managed, these factors can interfere with both equipment performance and biosafety conditions, as well as hinder laboratory workflows.

How Esco Integrated Automated Equipment into

the Biosafety Cabinet

At Esco, these challenges are addressed through a customized

engineering approach. Through in-depth discussions between

customers and Esco engineers, leads to a custom Class II BSC is

designed to safely fit automated equipment while ensuring proper

airflow and containment performance.

The customization extends beyond cabinet size. Internal and

external dimensions are adjusted to support equipment weight and

layout, while additional technical features are incorporated to

support stable operation. These may include vibration dampers,

thermal management, secure cable routers, and internal

connectivity solutions. This setup creates a controlled

environment for automated systems in operation.

Each customized BSC undergoes testing and validation to ensure performance meets customer requirements and applicable standards. This approach has been successfully implemented and validated for automated liquid handling systems and flow cytometers.

Esco’s BSCs offer fully customizable designs that fit existing laboratory spaces while maintaining their primary function of protecting users, products, and the environment. Well-designed automation integration is not merely an expanded workspace, but a purpose-built system that combines automation efficiency with fundamental biosafety protection.

To support this complex integration, Esco’s global service network and experienced technical team assist with installation and validation, to ongoing support. We would be pleased to support your project from conception through validation as you integrate automated equipment into a safe and sterile laboratory workflow.