Esco's Large BSC in Japan

In principle, cell sorting can refer to any technique that separates cells according to their properties. Both panning and magnetic cell sorting can be used for the selection of cells according to the expression of a surface molecule, because only such surface expressed molecules can be detected by these techniques using specific ligands. Both techniques also are bulk methods, which allow the rapid isolation of a large number of cells, however, without the ability to fine-grade according to expression level whereas they operate with a yes or no decision, unable to differentiate e.g. between low and high producing cells. Flow cytometry is the only method that allows both single cell selection as well as a (relative) quantification of the production of a specific compound. In addition, intracellular markers such as green fluorescent protein (GFP) or markers that describe a physiological activity, such as an enzyme activity or membrane potential, can only be measured and used for sorting by flow cytometry. Even though not a bulk method, desirable cells can be isolated quickly and efficiently with a traditional cell sorter one can easily look at a few million cells to find the rare outstanding performers (17 minutes at 1000 cells per second).

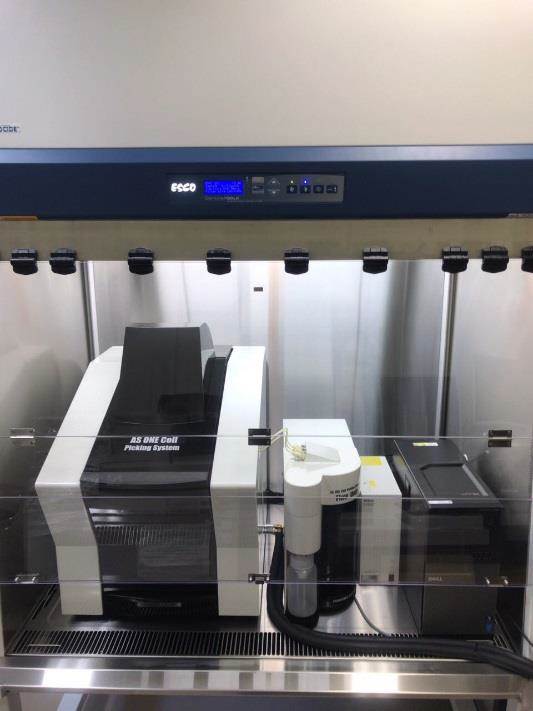

AS ONE Cell Picking System in Esco SC2-4A7-C

Figure 1. Esco SC2-4A7-C housing the cell sorter unit (AS ONE Cell Picking System)

Esco’s Streamline Class II Type A2 biological Safety Cabinet was installed in Japan last February 2017 in coordination with Waken Company, Limited. Esco SC2-4A7 is a customized version of a regular BSC unit with a 2380 mm external height.

Figure 2. AS ONE Cell Picking System

The cabinet was also configured with the specified features: hinged front window, 1060 mm internal height and 770 mm internal depth, and reinforced worktray for 100 Kg load, to accommodate the cell sorter unit (Figure 2) inside the cabinet.

With this project, Esco represents innovation and forward-thinking designs, which are all coupled with the highest standard quality for 39 years, remaining dedicated in delivering innovative solutions for the clinical, life sciences, research, industrial, laboratory, pharmaceutical and IVF community. As Esco takes the opportunity to respond to the world's needs, we aim not just to contribute in the advancement of scientific discoveries but also in making the world a safer, healthier and a better place to live in.

Esco Product Information:

ITEMCODE: 2011251

| General Specification, Streamline Max Class II, Biological Safety Cabinets | ||

| Model Name | SC2-4A7-C | |

| External Dimensions (WxDxH) | 1340 x 1060 x 1800 mm (52.6” x 41.7” x 70.8”) | |

| Internal/Work Area Dimensions (WxDxH) | 1220 x 770 x 1060 mm (48” x 30.3” x 41.7”) | |

| Usable Work Area | 0.58 m2 (6.0 sq. ft.) | |

| Tested Opening | 203 mm (8.0”) | |

| Max Sash Opening | 470 mm (18.5”) | |

| Average Airflow Velocity | Inflow | 0.53 m/s (105 fpm) |

| Downflow | 0.30 m/s (60 fpm) | |

| ULPA Filter Typical Efficiency | Exhaust | >99.999% for particle size between 0.1 to 0.3 microns, per IEST-RP-CC001.3 |

| Downflow | >99.999% MPPS as per EN1622 (H-14) EU | |

| Fluorescent Lamp | >1220 lux (>95 foot-candles) | |

| Cabinet Construction | Main Body | 1.2 mm (0.05”)/18 gauge EG Steel with ISOCIDETM Oven-baked Epoxy-polyester Powder Coating |

| Work Zone | Single Piece Tray: 1.5 mm (0.06”)/16 gauge SS 304, 4B Finish | |

| Electrical Rating | 100 VAC, 50/60 Hz, 1ø | |

REFERENCE:

- Mattanovich, Diethard, and Nicole Borth. “Applications of Cell Sorting in Biotechnology.” Microbial Cell Factories 5 (2006): 12. PMC. Web. 16 Mar. 2017