Feeling Alienated by Safety?

Protecting yourself from highly hazardous materials doesn’t have to make you look out of this world.

Are you confident with your isolator’s safe change filter feature?

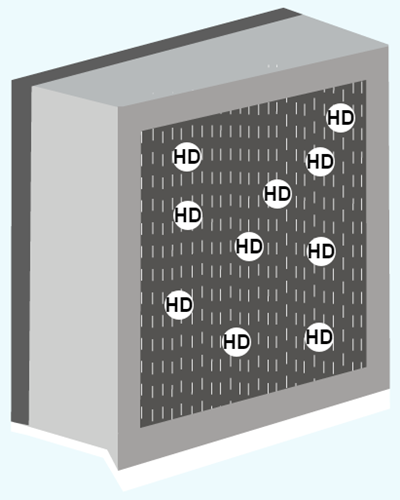

Equipped with high efficiency particulate air (HEPA) filters, an isolator is capable of containing the hazardous drugs manufactured.

HEPA filters then have direct contact and contain high level of hazardous drug concentration. This possess an occupational risk during HEPA filter replacement.

Why HEPA filter replacement poses a risk?

- Since HEPA filters prevent the passage of hazardous drugs out of the containment primary engineering control (C-PEC) such as isolators and BSCs, it gets loaded overtime.

- HEPA filters should be replaced when it gets loaded, damaged or when in-house safety protocol requires filter replacement.

- HEPA filters are fragile. During replacement, hazardous drug particles may be released to the area, thereby exposing the personnel and environment.

If not eliminated, how to minimize the risk?

SEE FULL ARTICLE>>>

For more information, please log on to www.escopharma.com or meet us at these following events:

|

Exhibition |

Date |

Venue |

Country |

|

Pharmtech Expo 2016 |

Nov. 22-25, 2016 |

Crocus Expo IEC, Pavilion 2 |

Moscow, Russia |

|

MENA Pharmaceutical Manufacturing Congress 2016 |

Nov. 29- Dec. 01, 2016 |

Le Meridien Jeddah |

Jeddah, KSA |

|

2016 ASHP Midyear Clinical Meeting and Exhibition |

Dec. 04-08, 2016 |

Mandalay Bay Convention Centre |

Las Vegas, Nevada USA |