How Effective are the Biosafety Cabinet's HEPA and ULPA Filters Against the SARS-CoV-2?

Ultra-Low Particulate Air (ULPA) filter captures microscopic particle size between 0.1 to 0.2 microns and has a typical efficiency of 99.999% per American IEST-RP-CC001.3 guidelines. It is comprised of filaments and fibers that carry a static charge which traps microorganisms, dusts, and particulate matters to produce clean air. On the other hand, High-Efficiency Particulate Air (HEPA) filter is 99.99% efficient at particle size of 0.3 microns. When combined with a cabinet airflow system and design, HEPA filter provides ISO class 5 work-zone cleanliness and ISO class 3 for ULPA filter. Therefore, ULPA offers 10x better filtration efficiency than HEPA filter and is used in an advanced biosafety cabinet.

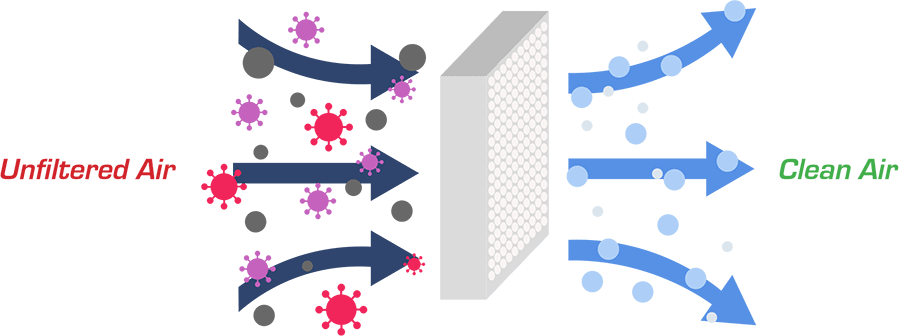

Figure 1. Movement of air with particulates passing through the ULPA filter.

Can it capture the SARS-CoV-2?

The SARS-CoV-2’s estimated size is around 0.12 μm, and there are doubts on the filter’s efficiency to capture the virus, especially with the HEPA filter. There is a common misconception that HEPA filters only capture particles with the size of 0.3 μm or larger. So here are some facts to prove the filter’s efficiency:

Particles with a size of more than 0.3 μm travel through the air filtration system and are retained within the filter due to inertia. While particles with less than 0.3 μm in size can be easily visualized to fly through the holes of HEPA filter. However, that is not the case. A fascinating interaction called Brownian Motion occurs and traps smaller particles as well.

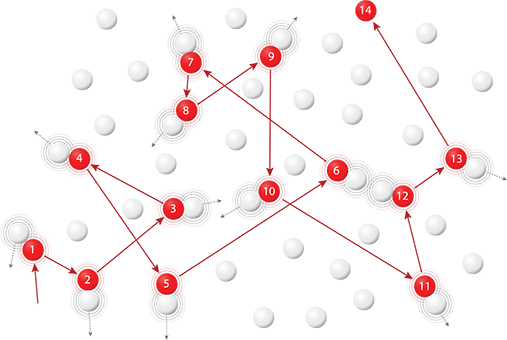

What is Brownian Motion?

The Brownian Motion causes the particles to bounce around and collide with each other, making them move in a random pattern and eventually hit the filter fibers and become trapped. That’s why smaller particles are easier to catch in both HEPA and ULPA filters.

Figure 2. Movement of particles during Brownian Motion.

According to a test conducted by NASA (2016), HEPA-rated media provides superior performance by removing virtually 100% of particulates. Moreover, there is only a slight drop in efficiency for particle size of around 0.3 μm — particles of this size are called Most Penetrating Particle Size (MPPS) in filter standards.

MPPS is the specific particle size that is most difficult to be captured by filter fibers. It is small enough to follow the air stream around the fibers, but it has enough mass that the Brownian motion effects minimally. Thus, particles size with less than 0.3 μm is in fact easier to capture in the HEPA and ULPA filters.

How to maximize guaranteed protection of a BSC filter?

Proper and timely maintenance. Services such as filter replacement, preventive maintenance, annual certification, and decontamination should be carried out regularly for optimal equipment performance. Thus, maximizes user protection, especially when used in a COVID-19 laboratory.

Figure 3. Filter integrity test conducted by a trained and certified engineer.

Preventive Maintenance

Prevention is key. This service procedure prevents unexpected downtimes and failures through routine maintenance and early detection of problems. The following are the procedures done when performing a preventive maintenance:

- Cleaning the work surfaces and walls with an appropriate disinfectant

- Removing stubborn stains or spots on the worktop

- Testing the audible and visual alarms

- Checking the cabinet’s mechanical and electrical functionality for any defect

Annual Certification

Hassle-free operation. The certification of a biosafety cabinet must be done annually to lessen the risk of unanticipated failure and prevent the user from any danger. It is comprised of a series of tests which includes filter integrity test to verify continued efficiency of HEPA and ULPA filters. The following tests are performed per the manufacturer’s specifications and relevant international standards such as NSF-49 for BSC:

- Inflow velocity test

- Downflow velocity test

- Filter integrity test

- Light intensity test

- Noise level test

- UV intensity test

Decontamination

Ready and safe usage. Filter replacement, unit installation, and relocation require proper decontamination. The following sterilants are used:

- Chlorine Dioxide

- Hydrogen Peroxide Vapour

- Formaldehyde (if requested by the client due to specific circumstances)

IQ/OQ Service

Audit-ready laboratory. Installation Qualification and Operational Qualification services ensure that equipment is installed and running smoothly by performing a series of tests based on international standards. Be prepared and worry less on your next audit. Esco can also train customer employees to perform IQ/OQ.

ESCO SERVICES PROVIDE A ONE-STOP SOLUTION FROM INSTALLATION TO DECOMMISSIONING OF YOUR EQUIPMENT!

Contact Us to schedule for equipment service

References:

[1] European Standard EN 1822-1:2009. 2009. "High efficiency air filters (EPA, HEPA and ULPA)".

[2] Perry, J.L. Agui, J.H. Vijayakumar, R. 2016. Submicron and Nanoparticulate Matter Removal by HEPA-Rated Media Filters and Packed Beds of Granular Materials. https://ntrs.nasa.gov/api/citations/20170005166/downloads/20170005166.pdf

[3] Scherzer, U. Brown, C. March 2020. Efficiency of HEPA filters. https://www.hamilton-medical.com/en/E-Learning-and-Education/Knowledge-Base/Knowledge-Base-Detail~2020-03-18~Efficiency-of-HEPA-filters~d5358f88-753e-4644-91c6-5c7b862e941f~.html.