Location Guidelines for Airflow Containment Equipment

Working in the laboratory may include handling hazardous samples such as chemicals, microorganisms, and drug compounds— all of which pose a threat to human health and the environment. An airflow containment equipment provides operator and sample protection from hazards by means of calculated airflow velocity, airflow direction, and filtration system. To guarantee optimum performance, it is vital to have these cabinets installed in proper location sites.

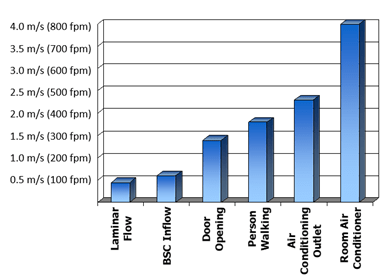

Due to the low face velocity of the cabinets, external airflow disturbances such as a door opening, a person walking, an air conditioner, or a fan can cause disruption and turbulence inside the cabinet’s work zone. Therefore, these cabinets must be installed or positioned in a way that optimally protects the airflow.

Fig. 1 Comparison of face velocities of equipment vs. Airflow disturbances

Protect the airflow! Follow these tips for the proper location of your containment devices.

- If possible, an initial site assessment must be done. This will provide an overview of the facility’s available space and will enable the engineers to plan for the installation and placement of the cabinets.

- Cabinets should never be placed in line with a doorway or a window that can be opened.

- Ensure that there are no room air diffusers, fans, extractors, or vents, placed directly towards the opening of the Biological Safety Cabinets, Laminar Flow Cabinets, and Fume Hoods.

- The position of the cabinet should satisfy the spatial requirements (e.g., vision, lighting, and convenience of access) of the operator and people working nearby.

- Exhaust Requirements:

- Maintain at least 300 mm (12”) clearance between the top of the cabinet and the ceiling.

- If the distance is less than 30 cm (1’), the airflow alarm system may need re-calibration.

- For proper exhaust filter leak scanning purposes, a minimum clearance of 50 cm is recommended.

Position Requirements

Allow a minimum clearance of 150 mm (6”) from walls. The sufficient space is provided for cleaning the cabinet sides and for unobstructed access to the main power supply point(s).

Maintain a distance of approximately 150 mm (6”) between two BSCs placed side by side. This spacing is necessary to allow the use of cable ports or service fixture connections.

Leave 150 mm (6”) min. clearance between the back of the BSC and the wall for service access.

Always keep at least 1,020 mm (40”) of unobstructed space in front of the BSC.

Allow at least 1,520 mm (60”) clearance in front of the cabinet from pedestrian routes, thoroughfares, or walkways.

Place the BSC at least 510 mm (20”) away from any perpendicular benchtop.

Do not install safety cabinets where airflow may be disturbed by other laboratory equipment. Maintain a minimum distance of 2,540 mm (100”) between the apertures of opposing cabinets, fume hoods, or similar equipment.

Place the cabinet with min distance of 1,520 mm (60”) of any doorway.

Door openings create air turbulence; place the BSC at least 1,020 mm (40”) from the swing side of any adjacent doorway.

Place the BSC at least 150 mm (6”) from the hinge side of any adjacent doorway.

SCAN HERE