I. CO₂ Incubator Overview

A CO₂ incubator is a vital apparatus in laboratories, creating a controlled space for cell and tissue cultures. Its precise regulation of temperature, humidity, and carbon dioxide levels is indispensable for cell growth and research applications, playing a pivotal role in advancing scientific understanding and medical breakthroughs.

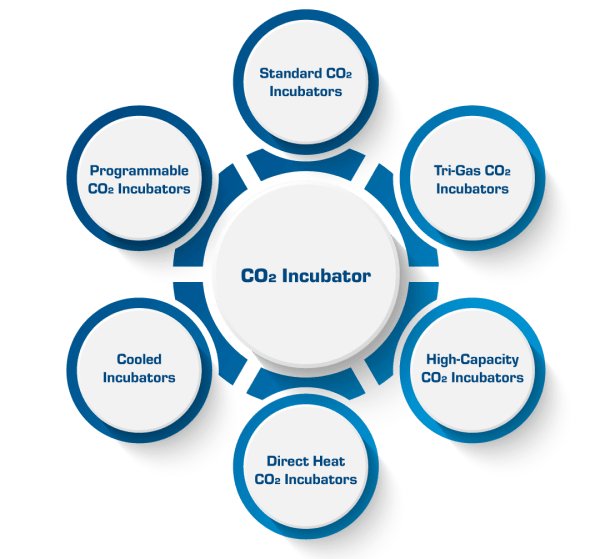

CO₂ Incubator Types

CO₂ incubators come in various types to meet different research and cell culture needs. The common types include:

a. Standard CO₂ Incubators

These are the basic models designed for routine cell culture applications, providing precise control over temperature, humidity, and CO₂ levels.

b. Tri-Gas CO₂ Incubators:

Some models offer tri-gas capabilities, allowing control of oxygen levels (O₂) in addition to CO₂. This is useful for creating specialized environments for specific cell culture requirements.

c. High-Capacity CO₂ Incubators:

Designed with larger capacities, these models are suitable for high-throughput laboratories or applications requiring a larger volume of cell cultures.

d. Direct Heat CO₂ Incubators:

These models use direct heating methods to ensure uniform temperature distribution within the incubator chamber.

Figure 1. Types of CO2 Incubators

e. Cooled Incubators:

Certain CO₂ incubators come equipped with cooling features, allowing researchers to maintain lower temperatures for specific applications.

f. Programmable CO₂ Incubators:

Some models feature programmable controls, enabling users to set and control parameters for temperature, humidity, and gas concentrations.

These types cater to different research demands, providing researchers with options based on the specific requirements of their experiments and cell culture applications.

CO₂ Incubator Applications

CO₂ incubators are versatile laboratory equipment designed to create controlled environments for cell and tissue culture. Their uses span various scientific disciplines, including:

CO₂ incubators are fundamental in cell biology research for maintaining cell lines and primary cells. They provide an optimal environment for studying cell behavior, growth, and function.

CO₂ incubators are utilized in IVF laboratories for culturing and maintaining embryos at optimal conditions before transfer.

In molecular biology applications, CO₂ incubators support techniques like polymerase chain reaction (PCR) and DNA sequencing. The controlled conditions inside the incubator ensure the success of enzymatic reactions.

In stem cell research, CO₂ incubators provide the controlled conditions necessary for the maintenance and differentiation of stem cells.

CO₂ incubators play a crucial role in medical research, particularly in tissue engineering and regenerative medicine. They provide the necessary conditions for cultivating cells used in these applications.

Researchers use CO₂ incubators to culture cancer cells for studying tumor biology, drug response, and potential therapeutic targets.

In drug development, CO₂ incubators are essential for cultivating cells used in drug testing and screening. They contribute to the study of cell responses to potential pharmaceutical compounds.

CO₂ incubators play a role in immunological research by providing an environment for the culture of immune cells and studying immune responses.

CO₂ incubators are used in microbiological research for bacterial and fungal cultures. The controlled environment aids in studying microbial growth and behavior.

In biotechnological applications, CO₂ incubators are used to produce cell-based products, such as vaccines, antibodies, and recombinant proteins.

The precise control of temperature, humidity, and CO₂ concentration in these incubators ensures reproducibility and accuracy in experiments, making them indispensable tools in various scientific and medical investigations.

Esco Lifesciences stands as a prominent manufacturer of laboratory equipment, including a diverse range of CO₂ incubators. Its lineup continues to expand, offering a variety of models to cater to the diverse needs of laboratory personnels and provide solutions for different applications. Its commitment is to provide a wide array of options for any specific requirements which empowers researchers and laboratories to make choices that best suit their specific experimental requirements.

II. Guide to Esco CO₂ Incubator Models

CO2 Incubator Model | CCL | CelCulture® with Copper Interior Chamber CCL-Cu | CelCulture® with Stainless Steel Exterior CCL-SS | CelCulture® for In Vitro Fertilization CCL-IVF | CelCulture® with Integrated Cooling System CCL-P | CelCulture® with High-Temperature CO2 Sensor CCL-HITEMP | CelCulture® with High Heat Sterilization CCL-HHS

| CLM

| |

|---|---|---|---|---|---|---|---|---|---|

Sizes Available | 50 L, 170 L, 240 L | 50 L, 170 L, 240 L | 50 L, 170 L, 240 L | 50 L, 170 L, 240 L | 170 L, 240 L | 50 L, 170 L, 240 L | 170 L, 240 L | 50 L, 170 L, 240 L | |

Certification | UL Listed | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

FDA Listed, Class II, 510k exempt medical device | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

CE Conformity | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

Temperature Range, °C | 5°C above ambient to 60°C | 5°C above ambient to 60°C | 5°C above ambient to 60°C | 5°C above ambient to 60°C | 8°C below ambient to 60°C | 5°C above ambient to 60°C | 5°C above ambient to 60°C | 5°C above ambient to 60°C | |

Construction | Main Body | Electrogalvanized steel with Isocide™ antimicrobial coating | Electrogalvanized steel with Isocide™ antimicrobial coating | Stainless Steel | Electrogalvanized steel with Isocide™ antimicrobial coating | Electrogalvanized steel with Isocide™ antimicrobial coating | Electrogalvanized steel with Isocide™ antimicrobial coating | Electrogalvanized steel with Isocide™ antimicrobial coating | Electrogalvanized steel with Isocide™ antimicrobial coating |

Chamber Material | Stainless Steel, 304 | Copper | Stainless Steel, 304 | Stainless Steel, 304 | Stainless Steel, 304 | Stainless Steel, 304 | Stainless Steel, 304 | Stainless Steel, 304 | |

Door type (Flat/Curved) | Flat/Curved Door | Curved Door | Curved Door | Curved Door | Curved Door | Curved Door | Curved Door | Curved Door | |

Sealed Inner Door Kit | Optional | Optional | Optional | Standard | Optional | Optional | No | Optional | |

CO2 Control | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

Suppressed O2 Control | Optional | Optional | Optional | Optional | Optional | Optional | Optional | No | |

Contamination Control Method | Decontamination Method | 90°C Moist Heat Decontamination Cycle (15 hours) | 90°C Moist Heat Decontamination Cycle (15 hours) | 90°C Moist Heat Decontamination Cycle (15 hours) | 90°C Moist Heat Decontamination Cycle (15 hours) | 90°C Moist Heat Decontamination Cycle (15 hours) | 90°C Moist Heat Decontamination Cycle (15 hours) | 180°C High Heat Sterilization Cycle (12 hours) | 90°C Moist Heat Decontamination Cycle (20 hours) |

UV Lamp* | Optional | Optional | Optional | No | Optional | No | No | Optional | |

ULPA Filter* | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

Gas Inline Filter | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

*Not available for 50 L models

Know more about the Esco CO₂ incubators.

III. Must-have Features of a CO₂ Incubator

Knowing the essential features of a CO₂ incubator is vital for maintaining optimal lab conditions. These features, such as precise temperature and humidity control, CO₂ regulation, and advanced monitoring, ensure reliable experimental outcomes, support safety, and extend equipment lifespan. Familiarity with these features aids researchers in selecting the right incubator for their specific needs, enhancing overall lab efficiency and success.

Ensure the right fit by checking these essential features before getting a new CO₂ incubator.

- Direct heat and air jacket

- Precise parameter control

- Forced convection design

- Heat-resistant sensors

- ULPA filtration system

- Moist heat decontamination/ high heat sterilization cycle

- Gas inlet filter

- Comprehensive user-configurable alarms

- Intelligent data and event logger records

- Seamless design for easier cleaning

- Removable ductwork, plenums, and shelves without tools

- Wide range of accessories

IV. Factors to Consider when Buying a CO₂ Incubator

Choosing the right CO₂ incubator for a laboratory is crucial for several reasons.

Cell Viability and Growth: The right CO₂ incubator provides precise control over temperature, humidity, and CO₂ levels, ensuring optimal conditions for cell viability and growth. This is essential for maintaining the health and functionality of cell cultures.

Experimental Reproducibility: Accurate and consistent experimental results depend on maintaining a stable and controlled environment. The right CO₂ incubator ensures reproducibility in experiments, reducing variability in outcomes.

Cell Culture Integrity: Different cell types may have specific requirements. Choosing the appropriate CO₂ incubator allows researchers to create conditions that mimic the physiological environment of the cells, preserving their integrity and functionality.

Specialized Applications: Certain experiments or applications may require unique conditions, such as low oxygen levels or specific temperature ranges. The right CO₂ incubator can offer features like tri-gas control or cooling capabilities to accommodate specialized needs.

Laboratory Compliance: Depending on the nature of the research, laboratories may need to comply with specific regulations or standards. Choosing a CO₂ incubator that meets these standards ensures the laboratory's compliance with relevant guidelines.

Energy Efficiency: Selecting a CO₂ incubator with energy-efficient features can contribute to cost savings and environmental sustainability. This is particularly important for laboratories seeking to minimize energy consumption.

User-Friendly Operation: The right CO₂ incubator should be user-friendly, with easy-to-use controls and features. This ensures that laboratory personnel can efficiently operate and maintain the equipment.

Equipment Longevity and Reliability: Investing in a quality CO₂ incubator increases the likelihood of the equipment's longevity and reliability. This reduces the risk of equipment failure, minimizing disruptions to ongoing experiments.

Adaptability to Future Research Needs: Laboratories evolve, and research needs may change over time. Choosing a versatile CO₂ incubator that can adapt to different experimental requirements allows for flexibility in accommodating future research needs.

FACTORS YOU SHOULD CONSIDER WHEN PURCHASING A CO2 INCUBATOR

- Type of CO₂ incubator

- Wide Temperature range

- Type of sensors

- Type of convection system

- Chamber material and design

- Wide Temperature range

- User-friendly control system

- Filtration system

- Decontamination/Sterilization Cycle

- Parameter control

- Recovery time of parameters

- Ergonomic design

- Testing and certifications

- Easy installation and set-up

- Warranty period

- After-sales service support

TYPICAL QUESTIONS YOU SHOULD ASK

- What are the physical parameters needed for my application?

- Are sensors removable during decontamination procedure?

- What size of CO₂ Incubator can be accommodated in my laboratory?

- What contamination control methods are available?

- What application needs suppression of oxygen?

- What are the common CO₂ incubator parts that need to be replaced annually?

- What are the accessories needed for my application?

- Do you have reliable after-sales service support?

- How long is the warranty period and what is its coverage?

- How often should it undergo preventive maintenance and how much will it cost?

WHY YOU NEED A NEW ONE

- Setting up a new or expanded laboratory facility.

- The existing unit has outdated specifications.

- Increased maintenance cost.

- Additional unit due to an increased laboratory workload.

- The unit is defective, and the service provider is inaccessible.

V. Safety Tips When Using CO₂ Incubators

Adhering to safety guidelines when working with CO₂ incubators is crucial to protect laboratory personnel, prevent contamination, and ensure equipment longevity. Compliance with safety protocols not only enhances the precision of experimental outcomes but also contributes to effective emergency response strategies.

Optimize your CO₂ incubator with these useful tips for efficient and effective usage.

How to Safeguard your Cell Culture from Contamination

Contamination of your cell culture can be the result of any of these conditions:

- Contaminated glass or plastic ware

- Contaminated media

- Contaminated cell line

- Improper technique

- Incubators and its components

- Airborne contaminants

- Lab environment & instruments

- Operators

Here are some safety tips to protect your cell cultures when using a CO2 incubator:

- CO2 Incubator needs to be cleaned with a disinfectant or detergent first and then rinsed with sterile water followed by 70% alcohol.

- Avoid using chlorine-based detergents/disinfectants.

- Change water (sterile water is recommended) in the water pan periodically.

- Allow autoclaved water to cool before adding to the water pan.

- Change the ULPA filter at least once a year or when the filter is dirty by visual inspection.

- Do not keep the CO2 Incubator door open for too long.

- Avoid talking, laughing, coughing, when opening CO2 Incubator door.

- Always wear gloves.

- Keep the air clean: no eating, drinking, and smoking.

- Always wear a clean lab coat.

- Avoid leaving medium and culture containers on containment surfaces.

Don't overlook these valuable CO₂ incubator tips. If you have any questions or are interested in Esco CO₂ incubators, leave us a message here: