Guide to CO₂ Incubator: Proper Installation and Maintenance

A CO2 incubator controls physical factors such as temperature, humidity, CO2 and O2 levels to mimic the natural environment of the cells. A well-designed CO2 incubator features high-quality incubation, precise heating and contamination control to guarantee optimal cell growth and development.

How to properly install a CO2 Incubator?

Proper installation is essential to ensure that the CO2 Incubator has optimal performance. Here is an installation checklist to guide you:

- The CO2 incubator should be placed on a dry, stable, and sturdy platform or on the various optionally available floors.

- Never place the CO2 incubator close to heating or cooling ducts, flammable materials, or devices that produce excess heat, such as autoclaves, radiators, ovens, and the like.

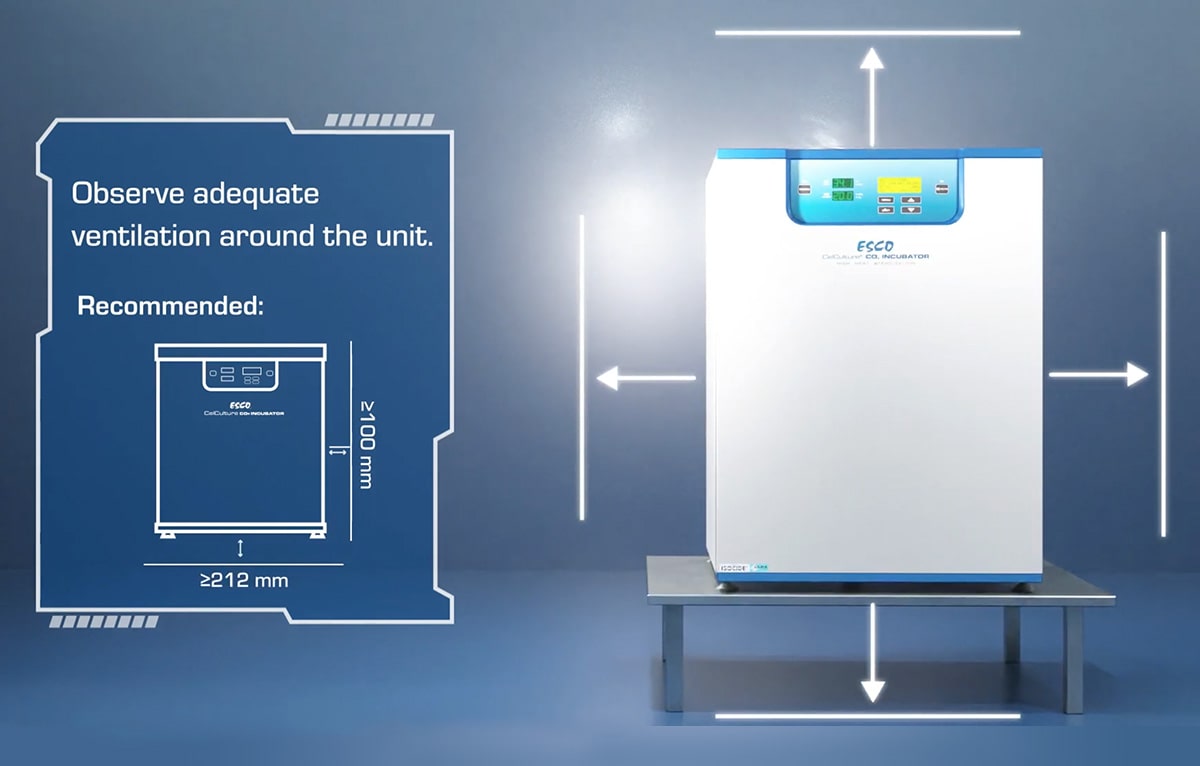

- Ensure adequate air ventilation around the CO2 incubator to allow proper heat and gas dissipation. Do not place the unit directly in the path of moving air currents.

- Ensure that the CO2 incubator is connected to a dedicated power source with protective grounding installed.

- Check if the CO2 incubator is even by placing a bubble level on the center top shelf of the unit.

How to maintain a CO2 Incubator?

Proper and timely maintenance is crucial for any device and the CO₂ incubator is no exception to this rule. Follow the maintenance checklist below to ensure the CO2 incubator’s optimum performance.

| Maintenance Checklist | ||||||

|---|---|---|---|---|---|---|

| Tasks to Perform | Frequency | |||||

| Daily | Weekly | Yearly | As Needed | |||

|

Check the CO₂/N₂ gas tank level

|

✓ | ||||

|

Check the water level in the humidity pan

|

✓ | ||||

|

Clean the CO₂ incubator's interior and exterior

|

✓ | ||||

|

Carry out general inspection

|

✓ | ||||

|

Calibrate the sensors

|

✓ | ✓ | |||

|

Change the ULPA filter (For 170L/240L units)

|

✓ | ||||

|

Change the inlet filters

|

✓ | ||||

|

Change the outer door magnetic gasket

|

✓ | ||||

|

Change the UV lamp*

|

✓ | ||||

|

Perform decontamination |

✓ | ||||

PRO TIP:

Remember to keep track of all maintenance work carried out on the CO2 incubator by keeping a service or maintenance log.

Cleaning Procedure

- During the cleaning process, the operator should use Personal Protective Equipment (PPE) according to the provisions of the laboratory.

- Prepare the materials needed for the cleaning process, such as mild soap solution, distilled water in a wash bottle, sponge, clean cloth or tissue, disinfectant, and wash tray or bucket (if a sink is not available).

- Metal surfaces can be cleaned using stainless steel cleaning agents. The inner glass door surfaces can be cleaned using glass cleaners. Never use chlorine-based disinfectants.

- Transfer all samples to another CO₂ incubator or store them in a safe place.

- Turn off and unplug the device. If needed, mark that the unit is deactivated or serviced.

- Remove the shelves, shelving system, top plenum, and humidity pan.

- Thoroughly remove dirt and residues from the surfaces of the workspace using a mild soap solution and a sponge or spray the appropriate disinfectant onto workspace surfaces and all dismantled parts. Allow the disinfectant to react as specified by the manufacturer.

- Do not spray disinfectant directly on the sensors, control panel, and surfaces near the electrical panel to prevent damage to the electrical parts. Use a cloth soaked with disinfectant to wipe the control panel and the exterior body.

- Rinse the soap solution or disinfectant twice using the distilled water in a wash bottle. If the part is hard to rinse with a wash bottle, use a wet sponge to remove the soap.

- Dry all rinsed parts with a clean, lint-free cloth or paper towel.

- Wipe the interior components and exterior surfaces with 70% ethanol, then allow them to dry.

- Re-assemble the unit and ensure the equipment is completely dry before commencing routine operation.

- Activate the decontamination/sterilization cycle program.

How to work safely with CO2 Incubator?

|

1. Use the CO₂ incubator only for incubating cells or tissues.For your safety, never load samples with unknown or potentially harmful compositions. |

|

2. Never leave the door open during normal operations.Leaving the door open causes the CO₂ incubator to overheat, pose a fire hazard, and expose the inner chamber to room contaminants. Reduce the frequency of door openings as much as possible. |

|

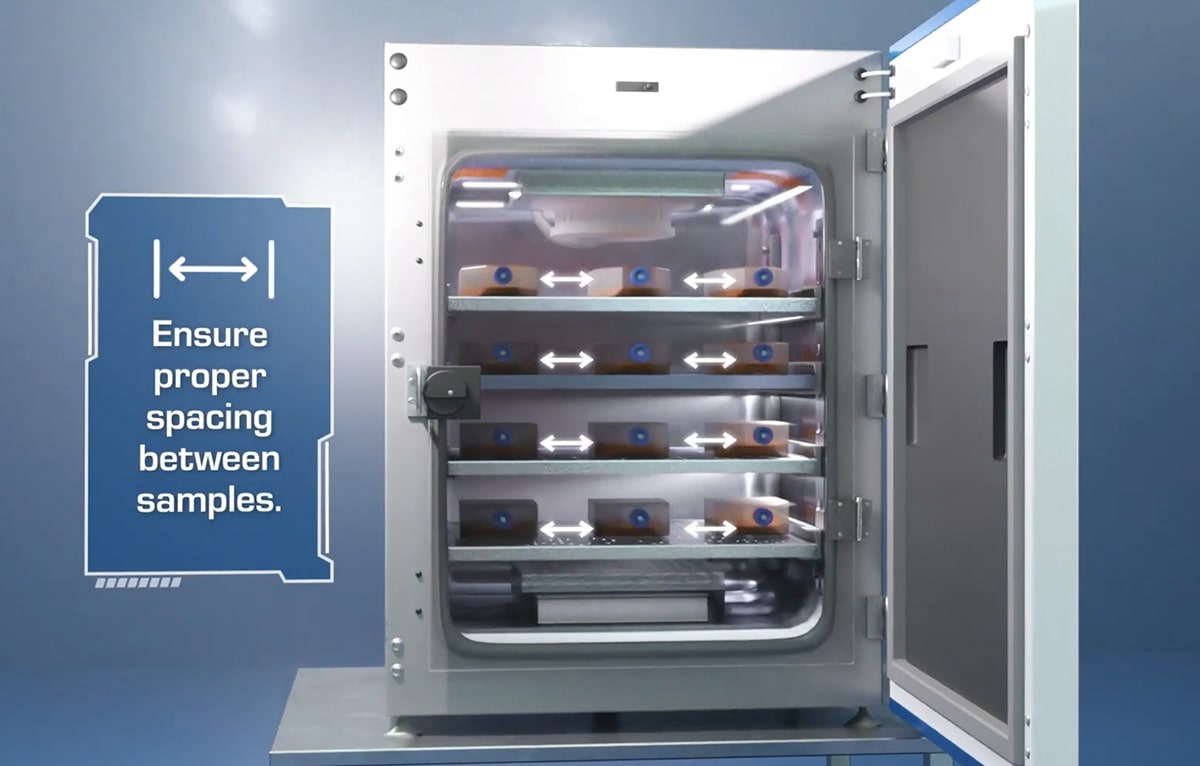

3. Ensure proper spacing between samples when loading the incubator.Never place any item touching the side walls of the CO2 incubator, as it may take a longer time to reach the set temperature. |

|

4. Do not place the CO2 incubator near flammable materials or equipment that produce excess heat.Equipment such as autoclaves, radiators, and ovens, which can produce too much heat, will greatly affect the CO₂ incubator’s performance. |

|

5. Ensure adequate ventilation around the equipment.Allow proper heat and gas dissipation around the CO₂ incubator, but do not place the unit directly in the path of moving air currents. |

|

6. Never place the equipment directly on the floor.Place the unit on top of a dry, stable, and sturdy working surface or on a floor stand to elevate the unit from the floor. |

|

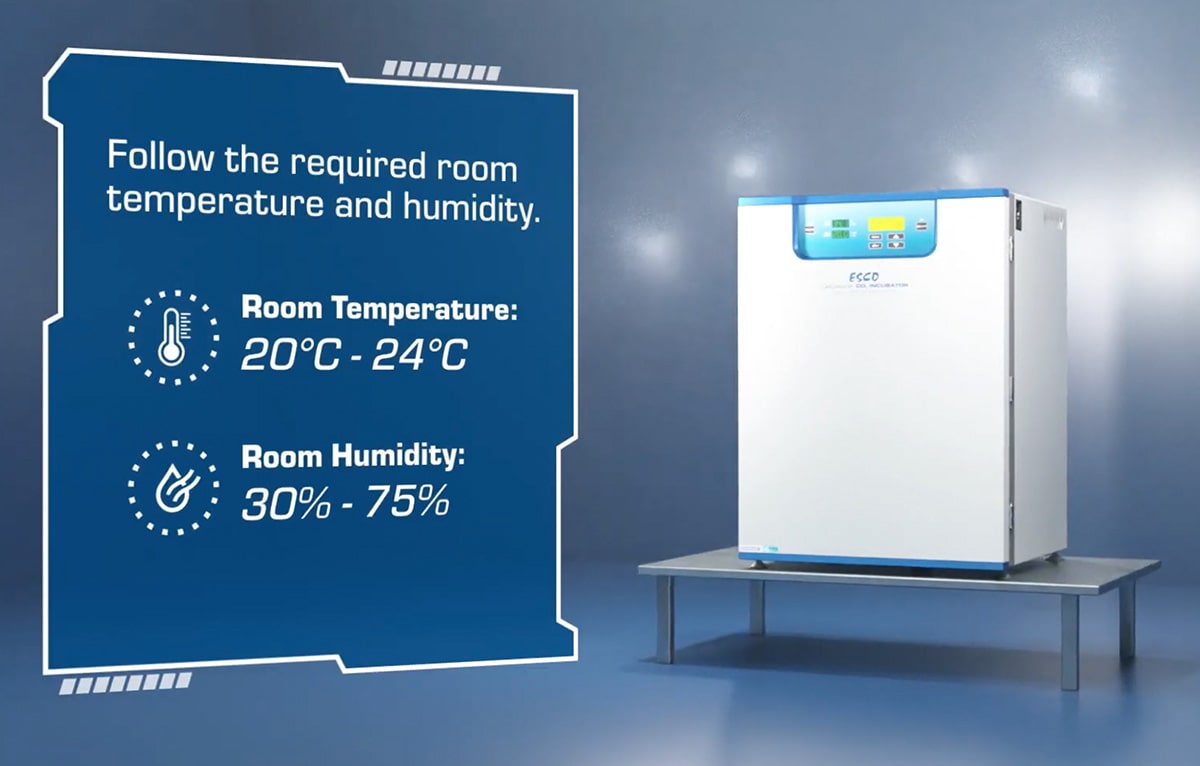

7. Follow the required room temperature and humidity according to the manufacturer.Environmental conditions are indicated in the user manual to maximize the use of the CO₂ incubator to its best performance. |

|

8. Ensure that the unit is connected to the correct power source.Follow the electrical requirements indicated in the serial number tag of the unit to prevent electrical hazard. |

|

9. Install a 2-stage gas pressure regulator on its gas tank.Pressure regulator will prevent over-pressurization of gas supply into the CO₂ incubator which may cause the tubing to burst. |

|

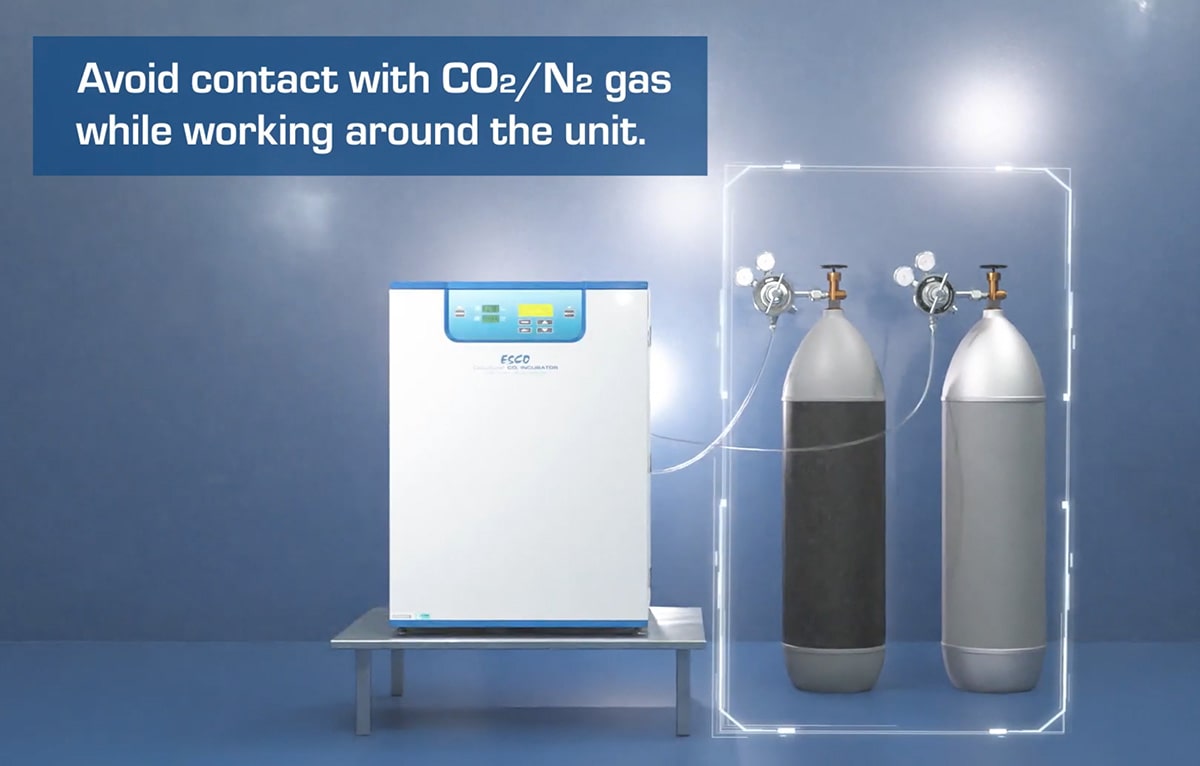

10. Avoid contact with CO₂/N₂ gas while working around the unit.During normal operations, small amounts of gas are released by the CO₂ incubator to its surroundings. These gases can have a suffocating effect in high concentrations. |

|

11. When filling the humidity pan, never use chlorinated tap water.Chlorine deteriorates the stainless-steel components of the CO₂ incubator. Tap water also produces a build-up of scale on the water pan. |

|

12. Check UV lamp functionality within less than 10 seconds only. |

|

13. Troubleshooting of the unit must be done only by qualified service personnel. |

Know more about the different applications suitable for CO₂ Incubator!

CO₂ incubators are widely used in scientific research. Typical fields of application include the following:

Neuroscience

Neurobiology is the study of nervous system cells and how these cells are arranged into functioning circuits that process information and regulate behavior. The development of human understanding of how the nervous system works has been largely attributed to the capacity to create in vitro cultures of neural and neuronal cells.

Liquid neuronal cell culture media must have the ideal ratio of minerals, vitamins, and salts, as well as the appropriate growth conditions (temperature, humidity, and CO2 level) to maintain the viability of tissue-extracted cells in the lab. The CO2 incubator handles the duty of controlling temperature, humidity, and O2/CO2 levels while providing cells with an environment free of contaminants.

Stem Cell Research

Stem cell research is the field of research where stem cells are studied for their possible applications in medicine. Stem cells are cells in the body that have the potential to develop into cells that perform a variety of functions in various parts of the body. Therefore, scientists are studying their ability to repair or regenerate damaged tissues and organs, which could lead to treatments for diseases like heart disease, cancer, diabetes, etc. Even though it was introduced in the late 1950s, there is still a lot of work to be done, hence the ongoing research.

In stem cell research, CO2 incubators are critical when it comes to handling cell cultures, maintaining sterile conditions, and ensuring maximum safety. It provides an optimal environment to develop cell and tissue cultures while protecting against potential contamination.

In Vitro Fertilization

In Vitro Fertilization (IVF) is a procedure where the sperm cell fertilizes an egg cell within an external environment instead of having it inside the human womb. The external environment must mimic a woman's uterus to facilitate successful fertilization. IVF technology employs CO2 incubators in this procedure to temporarily house the embryos while providing the ideal environmental conditions that are vital for the embryo's growth.

Presently, IVF applications use three types of incubators: dry CO2 incubators, humidified CO2 incubators, and time-lapse CO2 incubators, where the following parameters are accurately maintained and monitored:

- Temperature

- Oxygen Level

- Carbon Dioxide level

- Decontaminating Agents

The CO2 incubator functions as the artificial womb where embryos will develop until their maturity and then will be moved into an actual human uterus.

Tissue Engineering

Tissue Engineering is the process of developing functional tissues or biological substitutes by combining cells and biologically active molecules. Tissue-engineered products can restore, maintain, or fix damaged tissues and can be used to develop novel treatments.

Cellular processes play a key role in the replication of bioartificial organs; therefore, successful tissue culture and cell cultivation are vital. The design and use of equipment such as the CO2 Incubator and bioreactors must be considered to create valuable biomaterials. A reliable CO2 incubator should provide a humidified atmosphere with constant temperature and carbon dioxide control to achieve an optimal environment for cell growth.

Mammalian Cell Research

One of the fundamental principles of life sciences is mammalian cell culture. The rapid advancement in fields like cell biology, immunology, and cancer research would not be possible without the ability to grow cells in the laboratory. Mammalian cells, including primary cells and cell lines, are essential experimental materials widely used in research, clinical, and pharmaceutical applications.

Animal tissue cells can be isolated and cultured to produce functional cells or tissue analogs for regenerative medicine, virus vaccinations, and various therapeutic proteins and used as a research tool. Chemical engineers maximize the potential of mammalian cells, particularly in the design and optimization of processes. Unless a specific research goal is required, mammalian cells are typically cultivated at 37°C in a CO2 incubator with 5% CO2.

Cancer Research

Over the years, researchers have been committedly looking for and finding better ways to prevent, diagnose, and treat cancer. Progress in cancer research established terrific strides, and technologies used had to keep pace. One of the many engineering controls that significantly made cancer research advance is the CO2 incubator—a staple equipment in research laboratories.

Experimental and clinical studies have suggested that an environment with different Carbon dioxide (CO2) levels influences the growth of cultured cancer cells. Targeted therapies have revolutionized cancer treatments and pathophysiological high levels of CO2 are reported to be closely associated with the tumor microenvironment. It stimulates responses from diverse cancer cells to provide a better visual field for treating cancer. Although studies on the biological effects of elevated CO2 levels on cancer cells are still evolving, it is still of paramount importance that all possible outcomes are being exhausted to further progress cancer research.

A reliable CO2 incubator should control both the temperature and the CO2 level of the atmosphere in cultivating cells. Esco Lifesciences CO2 incubators provide rapid CO2, temperature, and humidity recovery with no overshot, making it an excellent choice in maintaining an optimal environment for the growth of different cells in several fields of research.

With correct installation and proper maintenance, the CO2 Incubator will last longer and will ensure safe incubation of cells and tissues. Esco Lifesciences is a one-stop shop that offers top-end CO2 incubators with several models, while providing installation and maintenance services.

Set up your laboratory with us. Contact us here!

Read more: CO2 Incubator Services, Choosing the right CO2 Incubator