The Class II Biosafety Cabinet is mainly used for handling pathogenic biological samples or for applications that require a sterile work zone. A biological safety cabinet is designed to have: an inflow for protecting the operator, an ULPA/HEPA-filtered downflow which creates an ISO Class 3 work surface that prevents cross contamination for protecting the sample, and an ULPA/HEPA-filtered exhaust for protecting the environment.

Must-have features to consider:

- Certified to NSF 49, EN 12469

- Options for side panel construction

- Choice of multipiece or single-piece worktrays

- Equipped with DC-ECM blower for 70% energy savings compared to AC motor

- Offers a broad range of sizes to fit any available laboratory space

- Has stable and self-compensating airflow, despite building voltage fluctuations & filter loading

- UV lamp for decontamination

- Airflow sensor to alert the user if airflow is sufficient for greater safety

- Alarm for unsafe sash conditions

- Ergonomically-designed raised arm rest helps prevent grille blocking and create a comfortable working posture

- Isocide™ powder coat that inhibits microbial growth

Labculture® G4 Class II Type A2 Biological Safety Cabinet

Specifications:

- Available in three sash opening models: 8”, 10”, and 12”

- Dimmable LED lighting system

- Centurion touchscreen controller

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- Stainless steel interior

- Single-piece work tray

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Labculture® Plus (S-series) G4 Class II Biological Safety Cabinet

Specifications:

- 200 mm (8”) sash opening

- Dimmable LED lighting system

- Centurion touchscreen controller

- Tiltable sash for easy glass cleaning

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- S-Series: Single-piece work tray, stainless steel sidewalls

- Motorized window

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Labculture® Plus (E-Series) G4 Class II Biological Safety Cabinet

Specifications:

- 200 mm (8”) sash opening

- Dimmable LED lighting system

- Centurion touchscreen controller

- Tiltable sash for easy glass cleaning

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- E-Series: Multi-piece work tray, glass sidewalls

- Motorized window

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Labculture® (G-series) G4 Class II Biological Safety Cabinet

Specifications:

- 200 mm sash opening

- Dimmable LED lighting system

- Centurion touchscreen controller

- Tiltable sash for easy glass cleaning

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- 21 CFR part 11 as standard feature

- Full SS316L working area, with single piece work tray

- Single sheet internal walls with smooth edges for easy cleaning

- Motorized window

- Equipped with dual DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 1.2m (4 ft) and 1.8m (6 ft)

- Available for customization of Stainless Steel 304/316L exterior cabinet material

Labculture® G4 Class II Type B2 (Total Exhaust) Biological Safety Cabinet, with BIBO

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- Stainless steel interior

- Single-piece work tray

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Labculture® G4 Class II Type B2 (Total Exhaust) Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- Stainless steel interior

- Single-piece work tray

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® NS (S-series) G4 Class II Type A2 Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- S-Series: Single-piece work tray, stainless steel sidewalls

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® NS (E-series) G4 Class II Type A2 Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- E-Series: Multi-piece work tray, glass sidewalls

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

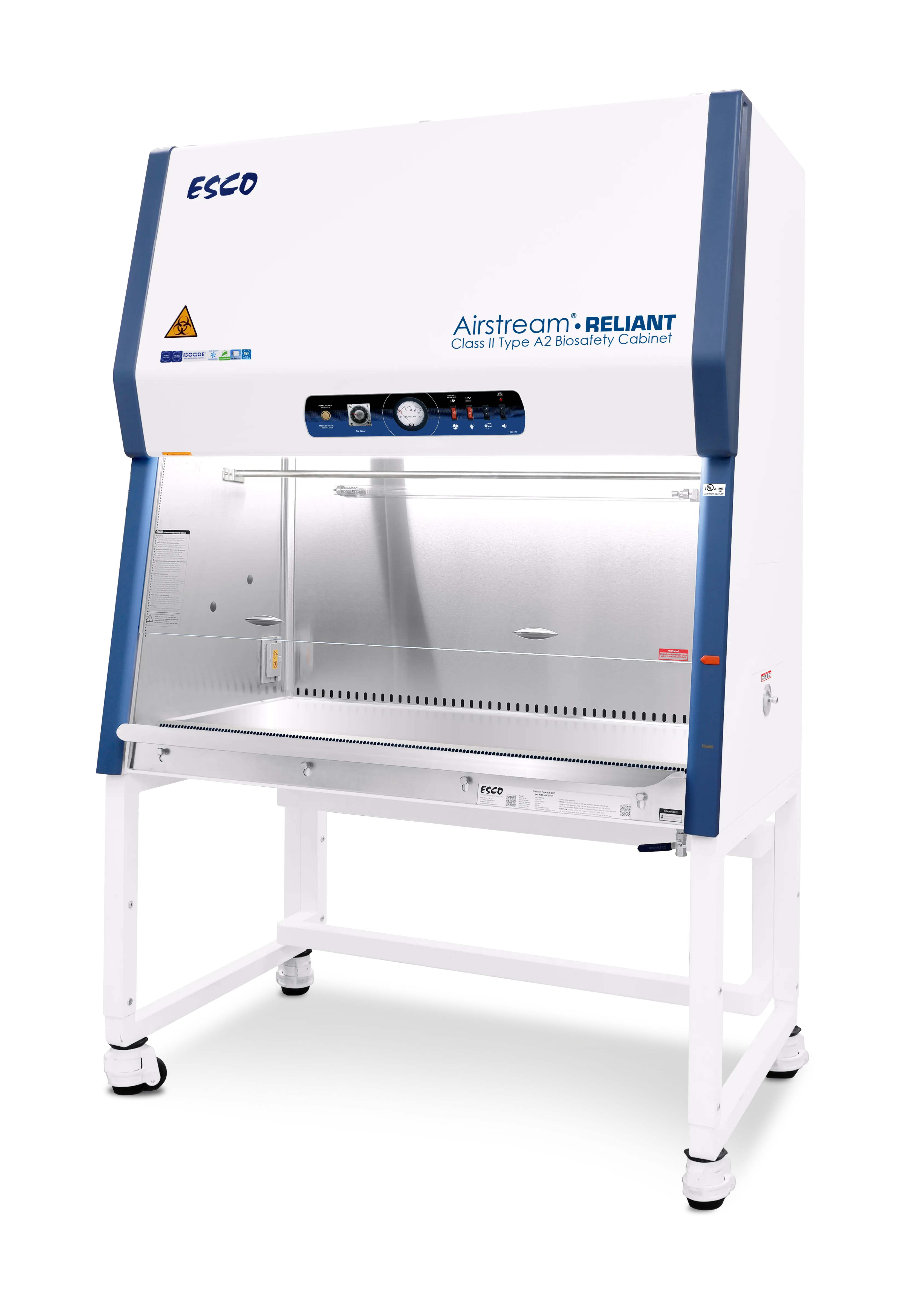

Airstream® Reliant G4 Class II Type A2 Biological Safety Cabinet

Specifications:

- Available in 8” sash height opening

- Compact-size and sleek exterior design

- BSC Rocker Switches and Pressure Gauge controller style

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- Default cable port

- Stainless steel interior

- Single-piece work tray

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® (E-series) G4 Class II Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS) Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- E-Series: Multi-piece work tray, glass sidewalls

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 2 ft, 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® (S-series) G4 Class II Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- Standby height that activates standby mode sustaining ISO Class 3 work zone as the fan runs at half speed

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- S-Series: Single-piece work tray, stainless steel sidewalls

- Equipped with DC ECM blower for up to 70% energy savings

- Low power consumption

- Available width sizes: 2 ft, 3 ft, 4 ft, 5 ft, and 6 ft

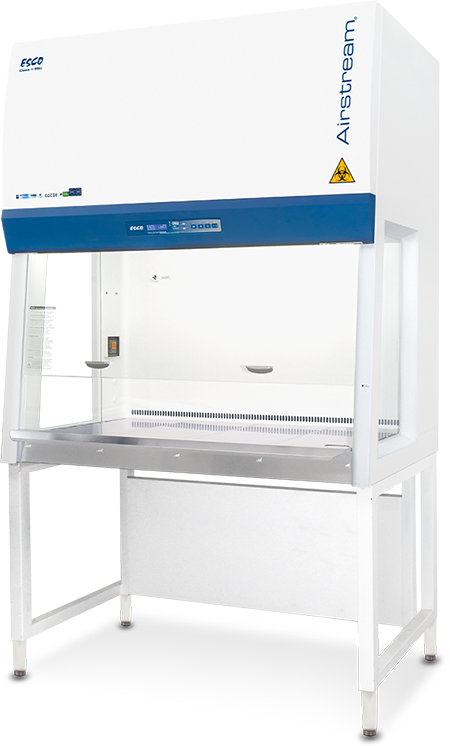

Streamline® (E-series) G4 Class II Biological Safety Cabinet, EN12469-certified

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- E-Series: Multi-piece work tray, glass sidewalls

- Available width sizes: 4 ft and 6 ft

Streamline® (S-series) G4 Class II Biological Safety Cabinet

Specifications:

- Dimmable LED lighting system

- Centurion touchscreen controller

- USB port to relay operational parameters to Building Management System (BMS)

- Remote Modbus

- Default cable port

- Optional 21 CFR Compliance

- S-Series: Single-piece work tray, stainless steel sidewalls

- Available width sizes: 4 ft and 6 ft

Airstream® Gen 3 Class II BSC- S Series

Specifications:

- Stainless Steel Interior

- Single-piece work tray

- Stainless steel sidewall

- Equipped with DC ECM motor for up to 70% energy savings

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 2 ft, 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® Gen 3 Class II BSC- E Series

Specifications:

- Multi-piece work tray

- Glass sidewall

- Equipped with DC ECM motor for up to 70% energy savings

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 2 ft, 3 ft, 4 ft, 5 ft, and 6 ft

Airstream® Plus Class II Biological Safety Cabinet – E Series

Specifications:

- Multi-piece work tray, stainless steel and glass hybrid side walls

- Equipped with two DC ECM blowers for up to 70% energy savings

- Motorized sash window

- LED lighting system

- Sentinel™ Gold Microprocessor controller

- Optional H2O2 Injection Port

- Available width sizes: 3 ft, 4 ft, 5 ft and 6 ft

Airstream® Plus Class II Biological Safety Cabinet – S Series

Specifications:

- Single-piece work tray, stainless steel side walls

- Equipped with DC ECM motor for up to 70% energy savings

- Motorized sash window

- LED lighting system

- Sentinel™ Gold Microprocessor controller

- Optional H2O2 Injection Port

- Available width sizes: 3 ft, 4 ft, 5 ft and 6 ft

Airstream® Gen 3 Class II Biological Safety Cabinet – G Series

Specifications:

- E.G. Steel back wall

- Multi-piece work tray

- Glass sidewall

- Equipped with two DC ECM motors for redundant system that provides protection in case of a power failure

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 4 ft and 6 ft

Airstream® Gen 3 Class II Biological Safety Cabinet – D Series

Specifications:

- Stainless steel Interior

- Single-piece work tray

- Stainless steel sidewall

- Equipped with two DC ECM motors for redundant system that provides protection in case of a power failure

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 4 ft and 6 ft

AC2-_E_-CN

AC2-_E_-CN

Airstream® Gen 3 Class II Type A2 Biological Safety Cabinet

Specifications:

- Has CFDA Class III medical device registration certificate

- Multi-piece work tray

- Glass sidewall

- Equipped with DC ECM motor for up to 70% energy savings

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 4 ft and 6 ft

Only available in China

AC2-_S_-CN

AC2-_S_-CN

Airstream® Gen 3 Class II Type A2 Biological Safety Cabinet

Specifications:

- Has CFDA Class III medical device registration certificate

- Stainless steel Interior

- Single-piece work tray

- Stainless Steel sidewall

- Equipped with DC ECM motor for up to 70% energy savings

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 4 ft and 6 ft

Only available in China

Airstream® Class II Type A2 Biological Safety Cabinet

Specifications:

- Compliant to AS 1807.22

- Single piece, recessed worktray

- Equipped with DC ECM motor for up to 70% energy savings

- Sentinel™ Gold Microprocessor controller

- Low noise level

- Available width sizes: 4 ft

Only available in Australia

NordicSafe® Class II Microbiological Safety Cabinet

Specifications:

- Quietest cabinet in the industry at 51 dBA

- Extremely low energy consumption (190 watts)

- Multi-piece work tray, stainless steel and glass side walls

- Equipped with energy-efficient DC ECM blower from ebm-papst Germany

- Motorized sash window

- Sentinel™ Gold Microprocessor controller

- Available width sizes: 3 ft, 4 ft, and 6 ft

Only for EU countries

Labculture® (Low Noise) Class II Biological Safety Cabinet

Specifications:

- ULPA Filter

- ISO Class 3 Work zone

- Equipped with DC ECM motor for up to 70% energy savings

- Dynamic Chamber™ prevents contaminants from escaping

- Sentinel™ Gold Microprocessor controller

- Angled front (8.5°) to optimize user comfort and ergonomics

- Low noise

- Available sizes: 3 ft, 4 ft, 5 ft, 6 ft, and 8 ft

Streamline® Class II BSC - E Series

Specifications:

- Multi-piece work tray

- Glass sidewall

- Sentinel™ Silver Microprocessor controller

- Available width sizes: 4 ft and 6 ft

Streamline® Class II BSC - S Series

Specifications:

- Single-piece work tray

- Stainless Steel sidewall

- Sentinel™ Silver Microprocessor controller

- Available width sizes: 4 ft and 6 ft

Labculture® Class II B1 Biological Safety Cabinet

Specifications:

- ULPA Filter

- ISO Class 3 Work zone

- Equipped with DC ECM motor for up to 70% energy savings

- Dynamic Chamber™ prevents contaminants from escaping

- Sentinel™ Gold Microprocessor controller

- Angled front (8.5°) to optimize user comfort and ergonomics.

- Available sizes: 4 ft

Airstream® Class II Type B2 (Total Exhaust) Biosafety Cabinets

Specifications:

- Dynamic Chamber™ Plenum design delivers quiet, uniform airflow

- Double-wall construction with negative pressure plenums

- Low noise level

- Available width sizes: 3 ft, 4 ft, 5 ft and 6 ft

- Compliant to NSF 49

-min.png)