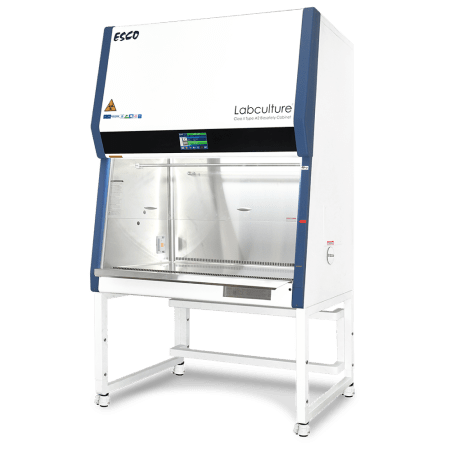

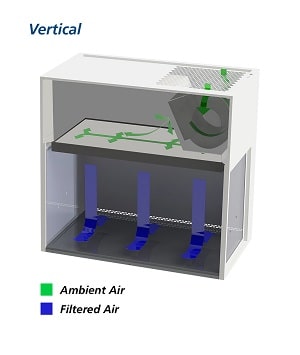

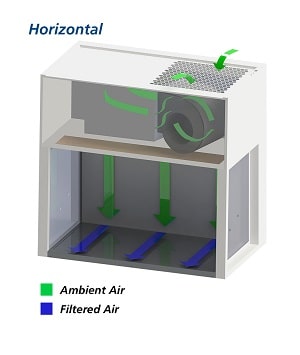

Using the term "Hood" to encompass airflow cabinets such as Biosafety, Laminar flow, and Fume hoods has become increasingly common. However, it is crucial to identify and select the appropriate hood for your specific application as they're used for different purposes. Each of them also has two major subcategories: Vertical and Horizontal for Laminar flow cabinets, A2 and B2 for Biosafety cabinets, and Ductless and Ducted for Fume hoods. Below are the technical differences between the six types.

| Equipment | Laminar Flow Cabinet | Biological Safety Cabinet | Fume Hood | |||

|---|---|---|---|---|---|---|

|

Types |

||||||

|

Application |

For handling non-pathogenic microorganisms, forensics, compounding sterile products. |

For plant tissue culture, media preparation, non-pathogenic samples. |

For handling pathogens. When optionally ducted, it can handle small amounts of naturally evaporating non-corrosive, volatile organic compounds. |

For handling pathogens. It has built-in ducting to handle medium amount of heated, non-corrosive, volatile organic compounds. |

For handling medium amount of naturally evaporating, mildly corrosive, limited range of chemicals matching the carbon filter, no pathogens. |

For handling large amounts of heated, corrosive, and wide range of chemicals but not pathogens. |

|

Protection Offered |

Product protection against outside contaminants but no operator protection. |

|

Operator protection against chemicals inside, but not pathogens, and no product protection against contaminants. |

|||

|

Operation protection against biohazards inside. Product protection against outside contaminants. |

Operation protection against biohazards and chemicals inside. Product protection against outside contaminants. |

|||||

|

Airflow |

Sterilize air through the filter and blow it across the work surface as a particle-free laminar air stream. |

Sterilize work zone through a purified air that travels in a horizontal, unidirectional stream and leaves the main work chamber across the entire open front of the cabinet. |

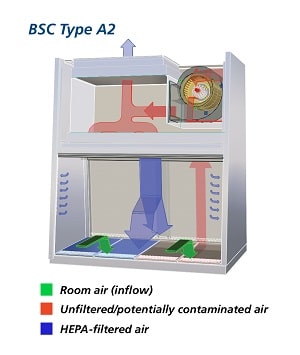

About 2/3 of air from the plenum is recirculated as downflow, and 1/3 is exhausted into the lab through exhaust HEPA filter. |

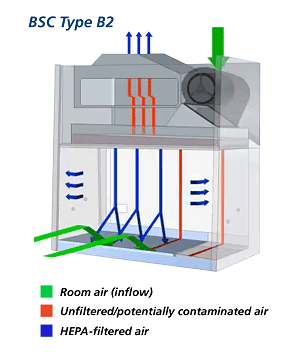

100% exhausted outside the building through exhaust HEPA filter, with no recirculation back into the work zone. |

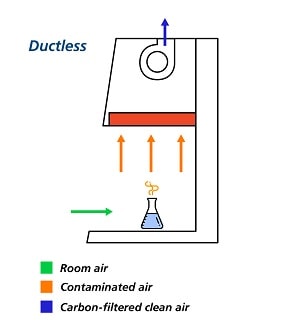

100% exhausted into the lab through carbon filter. |

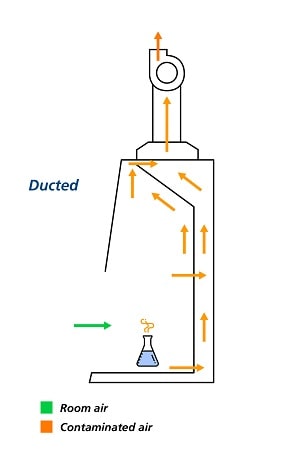

100% exhausted outside the building without any filter, hence risk assessment of what is being dumped into the outside environment is suggested. |

|

Requirements |

N/A | N/A | N/A | Ducting, rooftop exhaust blower | N/A | Ducting, rooftop exhaust blower |

|

Filtration |

HEPA Filters | Exhaust and Downflow HEPA/ULPA Filters | Carbon or HEPA Filter (depends on the client’s application) | No Filters | ||

|

Restrictions |

Not for handling hazardous pathogens and chemicals. | No corrosive chemicals. Even when ducted, this is not for forcibly evaporated chemicals due to air recirculation back to the work zone. | No corrosive chemicals. | Not for handling pathogens, sterile samples, and forcibly evaporated or highly corrosive chemicals. | Not for handling pathogens and sterile samples. | |

|

CLICK ON EACH CABINET TO LEARN MORE ABOUT IT |

||||||

Esco Lifesciences provides high-quality products and services based on years of experience. Your trusted partner for safeguarding research and elevating safety standards.

For more information on Hoods, please click the Cabinet Selection Guide button below.

Contact us for 1 week delivery from our large stock:

Esco Technologies, Inc.

Scientific Division

903 Sheehy Drive, Suite F, Horsham, PA 19044, USA

Toll-Free USA and Canada: 1-877-479-3726

215-441-9661

484-698-7757

[email protected]