Laminar Flow Cabinets are enclosed benches designed to prevent contamination to any particle sensitive materials. To warrant hassle-free operation, regular testing and maintenance should be done at least annually.

Certification

Downflow velocity test measures the downward movement of the air in the cabinet. It also determines the performance of the blower/s.

Filter integrity test verifies the continued efficiency of the filter by introducing particulates and measuring the output.

Light intensity test determines fluorescent lamp’s light intensity from the front to back centerline work surface level of the cabinet.

Noise Level tests is used to obtain the noise level of the cabinet during normal operation.*

Particle count test determines the air quality by counting and sizing the number of particles in the air and classify cleanliness level in a controlled environment.

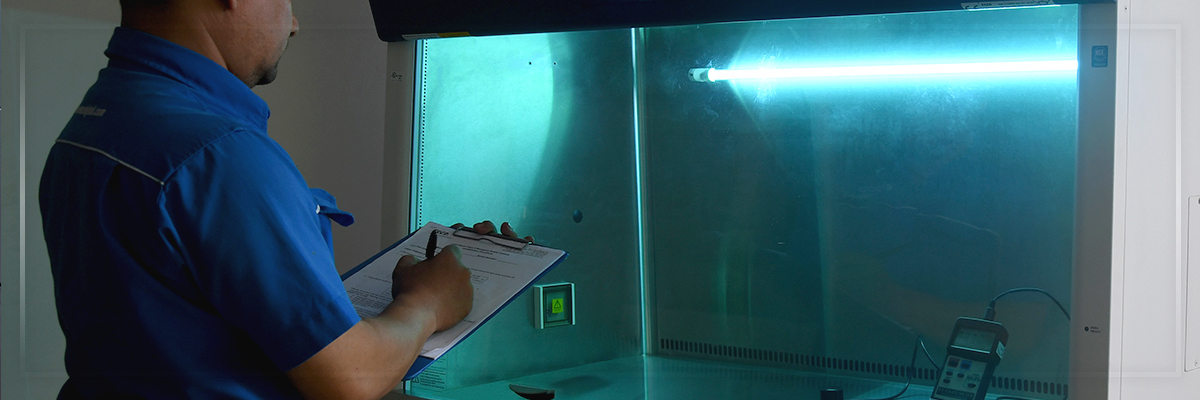

UV intensity test determines the light intensity of the UV lamp from the front to back centerline work surface level of the cabinet.*

*This test is optional for field testing.

IQ/OQ

Esco provides customers Installation Qualification/ Operation Qualification (IQ/OQ) protocol of our products. Esco can also perform these services directly on behalf of its customers or arrange them through independent approved local certifiers. The availability may vary from country to country and region to region. Also, Esco can train customer employees to perform IQ / OQ.

Preventive Maintenance

This includes cleaning the work surface and walls with appropriate disinfectant agent, removing of stubborn stains or spots on working surface, testing of audible and visual alarms, and checking of the cabinet’s mechanical and electrical functionality for any defect.

Troubleshooting and Parts Replacement

Esco provides replacements for consumable elements as well as any components that might fail while the product is in service.

- Blower

- Control System Membrane

- Filters (Main Filter and Pre-Filter)

- Fluorescent Light

- Magnetic Switch

- Sensors

- UV Lamp